Modulating control valve air brakes stand as a cornerstone of modern braking systems, revolutionizing the way vehicles come to a halt. These valves play a pivotal role in ensuring smooth, efficient, and responsive braking, making them an essential component for safety and performance.

In this comprehensive guide, we delve into the intricacies of modulating control valve air brakes, exploring their construction, operation, applications, maintenance, and future advancements.

As we embark on this journey, we will uncover the different types of modulating control valves and their diverse applications. We will examine their construction and operation in detail, unraveling the intricate flow of air that governs their functionality. Furthermore, we will explore the factors that influence their performance and efficiency, providing insights into their optimal operation.

1. Introduction

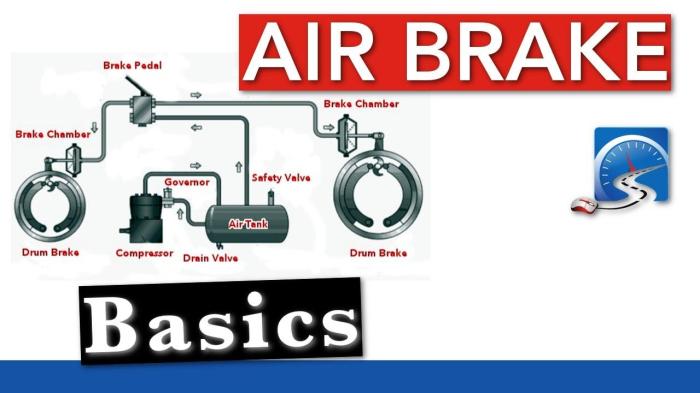

Modulating control valves play a crucial role in air brake systems, enabling precise and efficient control of braking force. These valves regulate the flow of compressed air to the brake actuators, modulating the pressure to achieve the desired braking effect.

By adjusting the air pressure, modulating control valves ensure optimal braking performance under varying load and operating conditions.

Modulating control valves are available in various types, each designed for specific applications and performance requirements. Some common types include proportional valves, which adjust air pressure based on an input signal, and electro-pneumatic valves, which combine electronic control with pneumatic actuation.

2. Construction and Operation

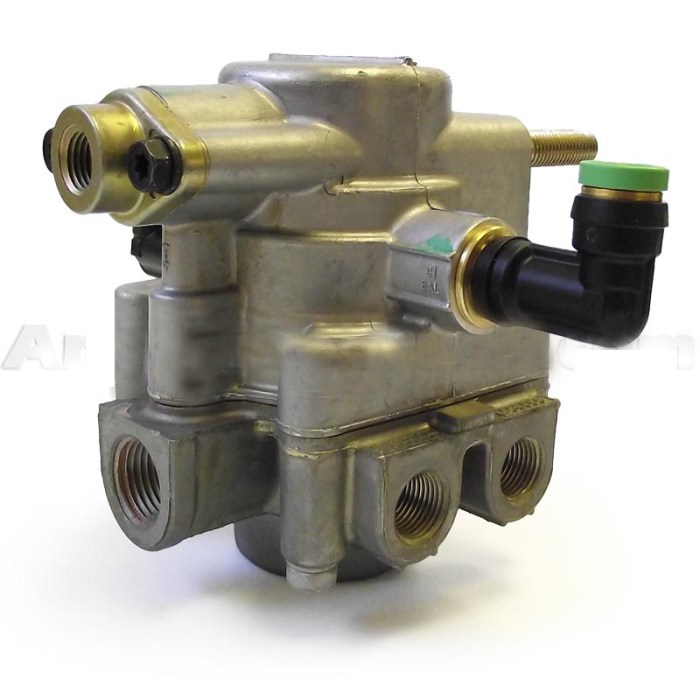

Modulating control valves typically consist of a valve body, a spool or diaphragm, and a control mechanism. The valve body houses the spool or diaphragm, which controls the flow of air through the valve. The control mechanism, which can be mechanical, electrical, or pneumatic, regulates the position of the spool or diaphragm, thereby adjusting the air pressure.

When the control mechanism receives a signal to increase braking force, it moves the spool or diaphragm to restrict the flow of air to the brake actuators. This reduction in air pressure causes the brake actuators to apply more force to the brake pads, increasing the braking effect.

Conversely, when the control mechanism receives a signal to decrease braking force, it moves the spool or diaphragm to allow more air to flow to the brake actuators, reducing the braking effect.

Factors that affect the performance and efficiency of modulating control valves include the size of the valve, the type of spool or diaphragm, and the control mechanism. The valve size determines the maximum flow rate of air that can pass through the valve, while the type of spool or diaphragm influences the precision and response time of the valve.

The control mechanism plays a critical role in ensuring accurate and reliable modulation of air pressure.

3. Applications: Modulating Control Valve Air Brakes

Modulating control valves are used in a wide range of air brake systems, including those found in commercial vehicles, buses, and trains. In commercial vehicles, modulating control valves are used to control the braking force on individual wheels, allowing for precise and balanced braking.

In buses, modulating control valves are used to control the braking force on the front and rear axles, ensuring optimal braking performance under varying load conditions.

In trains, modulating control valves are used to control the braking force on each car, enabling coordinated and effective braking throughout the train. Modulating control valves contribute to the safety and performance of air brake systems by providing precise control over braking force, reducing stopping distances, and improving vehicle stability during braking.

Advantages of using modulating control valves include improved braking performance, reduced stopping distances, and enhanced vehicle stability. Disadvantages include the potential for increased complexity and cost compared to simpler brake valves.

4. Maintenance and Troubleshooting

Proper maintenance and inspection of modulating control valves are essential to ensure optimal performance and safety. Regular inspections should include checking for leaks, corrosion, and damage to the valve body, spool or diaphragm, and control mechanism. Any signs of wear or damage should be addressed promptly to prevent potential failures.

Common problems that can occur with modulating control valves include sticking spools or diaphragms, clogged air passages, and faulty control mechanisms. Sticking spools or diaphragms can prevent the valve from modulating air pressure properly, leading to reduced braking performance. Clogged air passages can restrict the flow of air through the valve, causing similar issues.

Faulty control mechanisms can result in erratic or inaccurate modulation of air pressure.

Troubleshooting modulating control valves involves identifying the symptoms of the problem and tracing them back to the root cause. This may require testing the valve with compressed air and observing its response, as well as inspecting the control mechanism for proper operation.

Regular maintenance and prompt troubleshooting can help prevent failures and ensure the reliable operation of modulating control valves.

5. Future Developments

Future developments in modulating control valve technology are likely to focus on improving performance, efficiency, and reliability. Advancements in materials and manufacturing techniques may lead to valves with reduced friction and improved durability. New designs may incorporate innovative control mechanisms that offer greater precision and responsiveness.

The integration of electronic and digital technologies into modulating control valves is another area of potential development. This could enable more sophisticated control algorithms and advanced diagnostics, further enhancing the performance and safety of air brake systems.

As air brake systems continue to evolve, modulating control valves will play an increasingly critical role in ensuring optimal braking performance and safety. Ongoing advancements in technology are expected to drive the development of more efficient, reliable, and intelligent modulating control valves, contributing to the overall improvement of air brake systems.

FAQ Section

What is the primary function of a modulating control valve in an air brake system?

Modulating control valves regulate air pressure to control the braking force applied to each wheel, ensuring smooth and responsive braking.

What are the advantages of using modulating control valves in air brake systems?

Modulating control valves provide precise control over braking force, reduce stopping distances, improve vehicle stability, and enhance overall braking performance.

How do modulating control valves contribute to vehicle safety?

By precisely controlling braking force, modulating control valves help prevent wheel lock-up, reduce skidding, and maintain vehicle stability during braking, enhancing overall safety.